Plywood has long been hailed as one of the most versatile building materials, and in India, it takes on an even more adaptable form – Flexible Plywood. This remarkable material has revolutionized the construction and interior design industry with its ability to bend and conform to various shapes and curves. In this comprehensive guide, we will delve into the fascinating realm of Flexible Plywood in India, uncovering its characteristics, applications, advantages, and much more.

Understanding Flexible Plywood

What is Flexible Plywood?

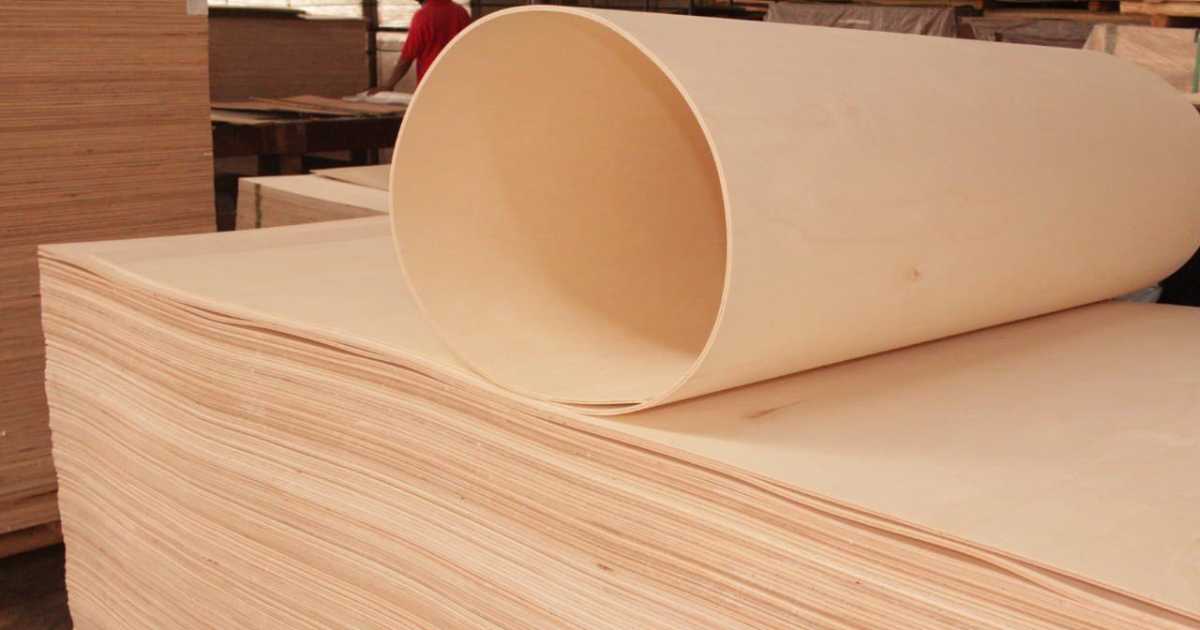

Flexible Plywood, also known as bendable plywood, is a unique and innovative variant of traditional plywood. While standard plywood is rigid and cannot be easily bent or shaped without breaking, flexible plywood is specially engineered to be pliable. It can be effortlessly bent, curved, and molded to suit a wide range of design needs.

Composition

Flexible Plywood is crafted using the same fundamental principles as standard plywood. It consists of several thin layers or plies of wood veneer that are bonded together with adhesive. However, what sets flexible plywood apart is the strategic arrangement of these layers and the use of a specific type of veneer that imparts flexibility.

The key components of flexible plywood include:

- Veneer Sheets: Thin wood veneer sheets make up the layers of flexible plywood. These veneers can be sourced from various wood species, including hardwoods like birch, beech, or tropical woods like okoume.

- Adhesive: High-quality adhesive is used to bond the veneer sheets together. The adhesive used for flexible plywood is chosen for its ability to maintain flexibility even after bonding.

- Grain Direction: The veneer layers in flexible plywood are typically arranged in a manner that allows for bending along one axis while remaining rigid along the other. This grain orientation is crucial for achieving flexibility.

Manufacturing Process

The production of flexible plywood involves a meticulous manufacturing process that ensures its unique properties:

- Veneer Selection: High-quality veneer sheets are carefully chosen for their strength and flexibility characteristics.

- Gluing: The veneer sheets are coated with a flexible adhesive that allows them to bend without cracking or breaking.

- Layer Arrangement: The veneer sheets are stacked in such a way that their grain direction is uniform, allowing for bending along a specific axis.

- Pressing: The veneer stack is placed in a hydraulic press, where it is subjected to controlled pressure and heat. This process activates the adhesive and bonds the veneer layers together.

- Cutting and Trimming: Once the flexible plywood sheets are formed, they are cut and trimmed to the desired size and shape.

Advantages of Flexible Plywood

Flexible Plywood offers a host of advantages that make it a preferred choice in various applications:

1. Bendability

The primary advantage of flexible plywood is its ability to bend and conform to curves and shapes. This property opens up a world of design possibilities, enabling the creation of curved furniture, arches, and other intricate designs.

2. Versatility

Flexible plywood is incredibly versatile and can be used in both interior and exterior applications. Its ability to adapt to different contours makes it ideal for projects that require unique shapes and structures.

3. Strength and Durability

Despite its pliability, flexible plywood maintains its structural integrity. It can withstand moderate loads and is suitable for both decorative and functional applications.

4. Time and Cost Efficiency

Using flexible plywood can significantly reduce construction and installation time, as it eliminates the need for complex joinery or the use of multiple materials to achieve curved designs.

5. Aesthetic Appeal

Flexible plywood provides a smooth, uniform surface that is well-suited for various finishes, including veneers, laminates, and paint, allowing for customized aesthetics.

6. Eco-Friendly

Many flexible plywood manufacturers prioritize sustainable sourcing and production practices, making it an eco-friendly choice for environmentally conscious projects.

Applications of Flexible Plywood

Flexible Plywood’s unique properties make it suitable for a wide range of applications across various industries. Some of its primary uses include:

1. Curved Furniture

Flexible plywood is a popular choice for crafting curved and contoured furniture pieces such as chairs, tables, and sofas. Its ability to bend allows for ergonomic and aesthetically pleasing designs.

2. Architectural Features

In architecture and interior design, flexible plywood is used to create curved walls, ceilings, and partitions, adding a touch of elegance and sophistication to spaces.

3. Marine Interiors

In the marine industry, where space is limited and curved surfaces are common, flexible plywood is used for boat interiors, cabinetry, and other curved components.

4. Retail Displays

Retail spaces often employ flexible plywood for unique and eye-catching displays and fixtures that draw customers’ attention.

5. Exhibition Booths

In the events and exhibition industry, flexible plywood is used to create innovative and attention-grabbing booth designs that stand out in crowded environments.

6. Art and Sculpture

Artists and sculptors use flexible plywood as a versatile material for creating intricate and dynamic art installations and sculptures.

7. Automotive Interiors

Flexible plywood finds its place in the automotive industry for crafting curved interior components such as dashboards and door panels.

8. Musical Instruments

In the realm of musical instrument manufacturing, flexible plywood is used for curved parts in the construction of instruments like violins and acoustic guitars.

Maintenance and Care

Proper maintenance and care can extend the lifespan of flexible plywood and ensure that it continues to perform well in its intended applications:

- Surface Protection: Apply appropriate finishes, such as veneers, laminates, or paints, to protect the surface of flexible plywood from wear and tear.

- Avoid Over-bending: While flexible plywood is designed to bend, avoid over-bending it beyond its natural flexibility to prevent stress on the material.

- Protection from Moisture: When used in outdoor applications, ensure that flexible plywood is adequately protected from prolonged exposure to moisture to prevent delamination.

- Regular Cleaning: Clean the surface of flexible plywood with a soft, damp cloth to remove dust and dirt. Avoid abrasive cleaners that could damage the finish.

- Repairs: If the flexible plywood sustains any damage, such as cracks or dents, it’s essential to address it promptly to prevent further deterioration.

Conclusion

Flexible Plywood is a testament to human innovation and the limitless possibilities that come with it. In India, this remarkable material has transcended traditional constraints, allowing architects, designers, and builders to breathe life into their most creative visions. Its ability to bend and adapt makes it an invaluable asset in crafting unique and visually stunning structures and designs. As the construction and design industries in India continue to evolve, flexible plywood stands ready to embrace the challenges of shaping the future with its pliable nature and boundless potential.